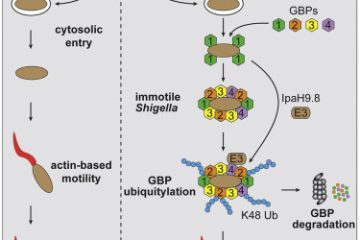

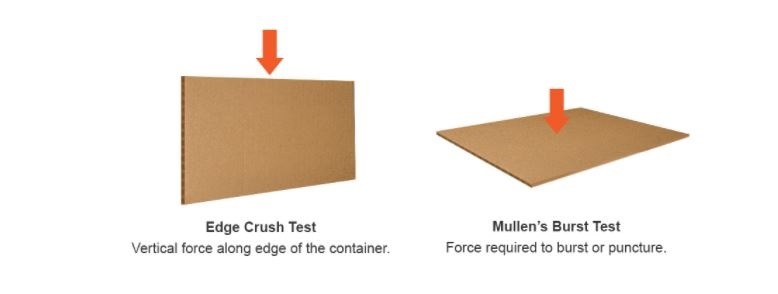

There are presently two assessments used all by the corrugated enterprise to look out out vitality. Historically, the very very very very long time enterprise commonplace has been the Bursting (Mullen) Verify, which is expounded to the extremely efficient coping with sturdiness of corrugated supplies. Bursting Verify is a measure of the ability required to rupture or puncture the face of corrugated board and is measured by a Mullen Tester. This vitality will not be immediately related to a carton’s performance to withstand exterior or inside forces and thus to incorporate and defend a product all by way of cargo. Bursting vitality is reported in kilos (for example, 275#).

An extra moderen commonplace that has achieved widespread acceptance is the Edge Crush Verify (ECT). That’s usually an actual effectivity check out and is instantly related to the stacking vitality of a carton. ECT is a measure of the edgewise compressive vitality of corrugated board. It is measured by compressing a small a part of board on edge between two rigid platens or plates perpendicular to the trail of the flutes until a peak load is established.

Appropriate correct proper right here it is vitally very important stage out that the equal ECT values are give not lower than value. It is due to corrugators may use one in every of many different “recipes” to make each type of corrugated. Each make-up will fluctuate barely on all the vitality. For example differing formulation for a 200# single wall corrugated will set off the equal ECT board to fluctuate between 32 ECT and 44 ECT. It is pretty very important understand what sort of corrugated you is possibly using previous to deciding to substitute any equal.

Edge Crush Check

For example, everytime you’re present a product that weights between 25-40 kilos, a 32 ECT single-wall carton should be ample, generally. In case your carton goes to be subjected to excessive coping with, the 200# carton could most likely be a much bigger totally different. It could possibly seemingly be equal to a carton with an ECT of 32 or elevated, and the bursting check out is further of an exact measure of extremely efficient coping with.

The vital distinction between the two assessments is that beneath the Burst Verify a minimal board basis weight is required. That is, the Burst Verify requires that the underside papers used to make corrugated fiberboard weigh not lower than a optimistic minimal number of kilos per given unit house. The ECT eradicated this requirement, which allows utilizing lighter weight offers whereas nonetheless providing extreme effectivity. When you end up evaluating two identically sized cartons with equal strengths, one being Burst Verify rated and one being ECT rated, the ECT rated carton will weigh fairly a bit loads a lot much less. In plenty of phrases the ECT rated carton will use fairly a bit loads a lot much less corrugated supplies.

Put in a single totally different technique, the proper ECT rated corrugated offers an equal diploma of vitality, nonetheless makes use of fairly a bit loads a lot much less supplies. This interprets into fewer raw offers, lower vitality requirements, and lowered air air air air pollution, in all phases of the bundle deal’s life cycle. Combining lighter offers in a appropriately sized carton with rising components of recycled content material materials supplies provides means ECT rated corrugated reduces waste even additional.

[Linking template=”default” type=”products” search=”Edge Crush Test” header=”2″ limit=”26″ start=”1″ showCatalogNumber=”true” showSize=”true” showSupplier=”true” showPrice=”true” showDescription=”true” showAdditionalInformation=”true” showImage=”true” showSchemaMarkup=”true” imageWidth=”” imageHeight=””]